The Human Cost of Hail: More Than Just a Roof Problem

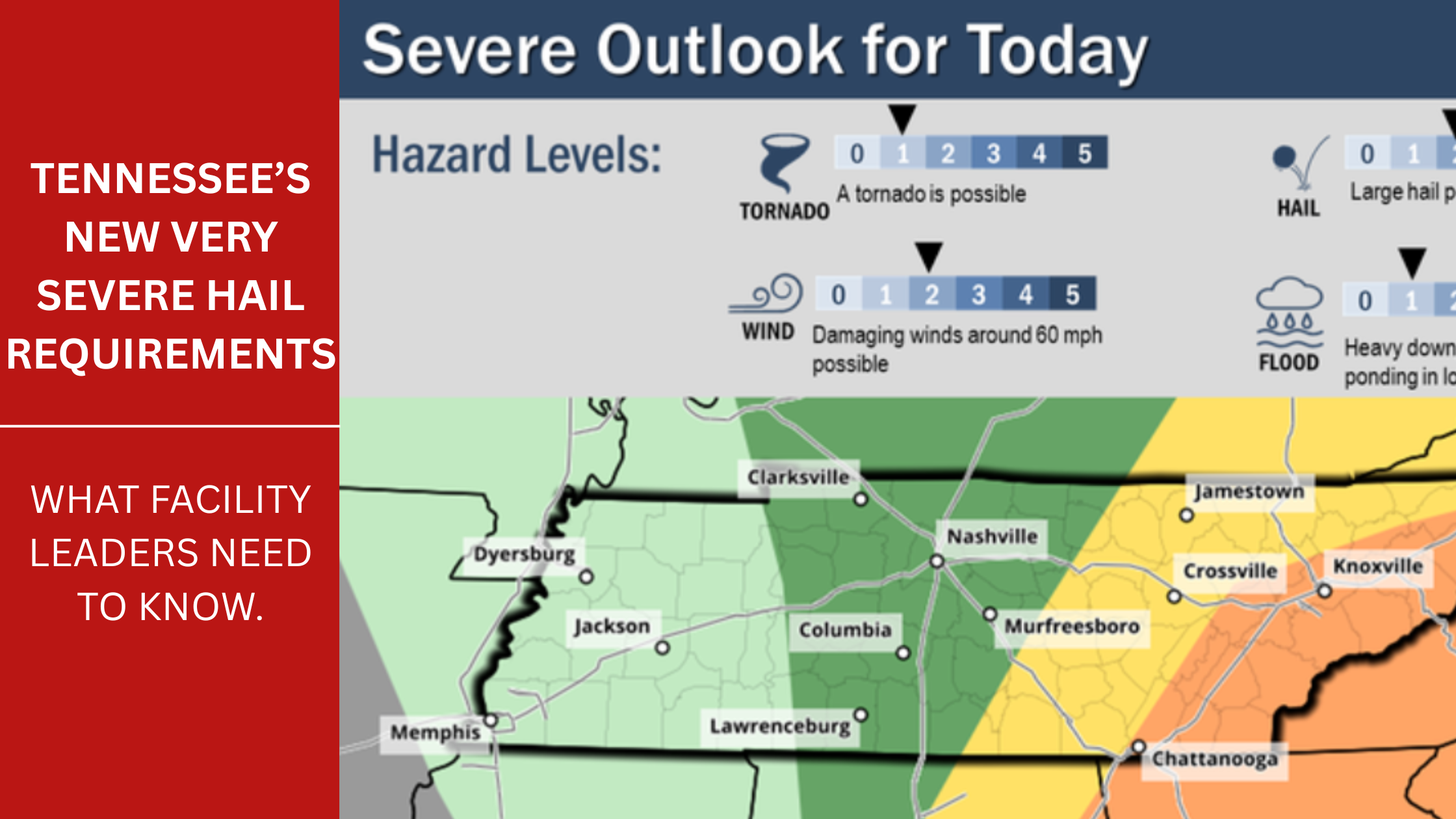

When a hailstorm hits, it’s not just the roof that takes a beating. For facility operators, the stress and anxiety that follow can be overwhelming. There’s the fear of catastrophic structural damage, the burden of coordinating emergency repairs, and the constant pressure to protect people, property, and operations.

Imagine a school forced to cancel classes, a hospital worried about water infiltration into critical care areas, or a manufacturing plant halting production mid-shift. These are not abstract risks, they are very real scenarios that can disrupt lives, delay essential services, and undermine trust. When your roof fails, it’s not just shingles or membranes that are at stake, it is the continuity of your mission and the safety of everyone inside.

What is VSH Roofing and Why It’s Different

Very Severe Hail (VSH) roofing systems are specifically engineered to endure the most destructive hail events. This is not a marketing label, it is backed by decades of scientific research and loss-prevention engineering from FM Global, one of the world’s leading commercial property insurers and engineering organizations.

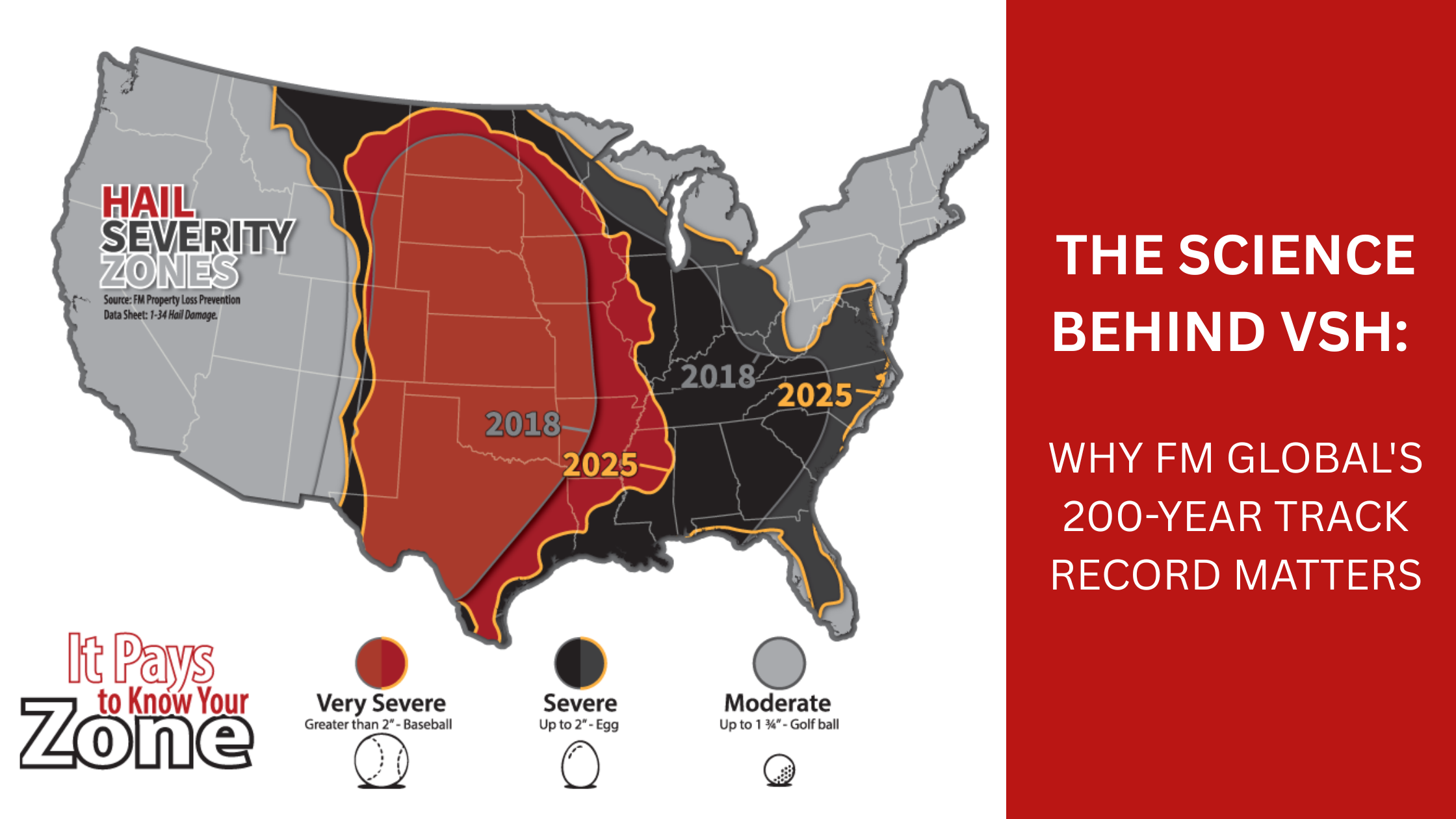

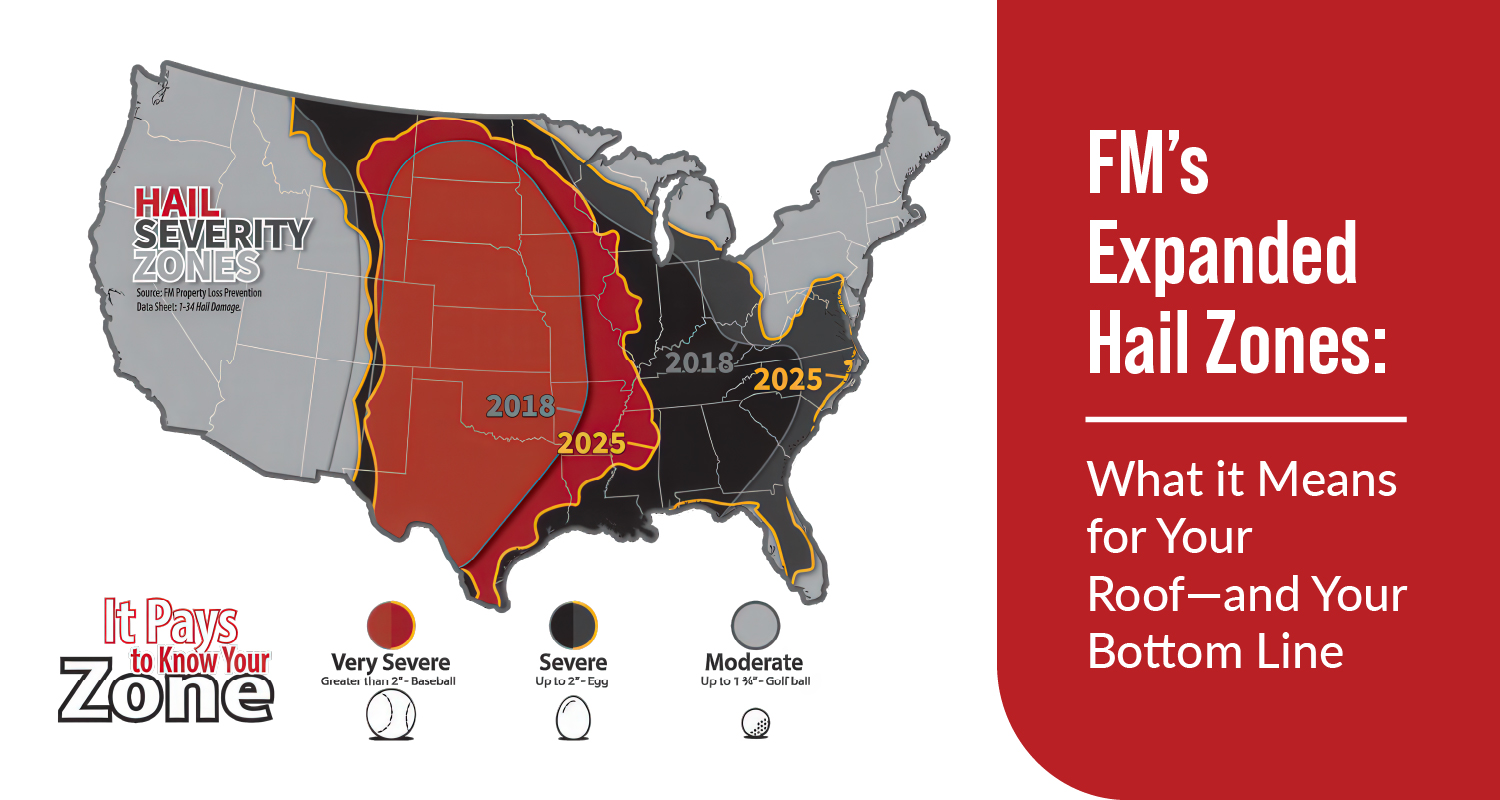

FM Global has spent more than 200 years studying how structures fail under extreme weather. Their findings have shaped the Loss Prevention Data Sheet 1-34, Hail Damage,

which defines hail-risk zones across the U.S. and establishes performance standards for roof systems.

In 2018, FM Global introduced the VSH classification into LPDS 1-34, acknowledging that hail events were becoming more severe and demanding more resilient roofing systems.

The Rigorous Science Behind VSH Testing

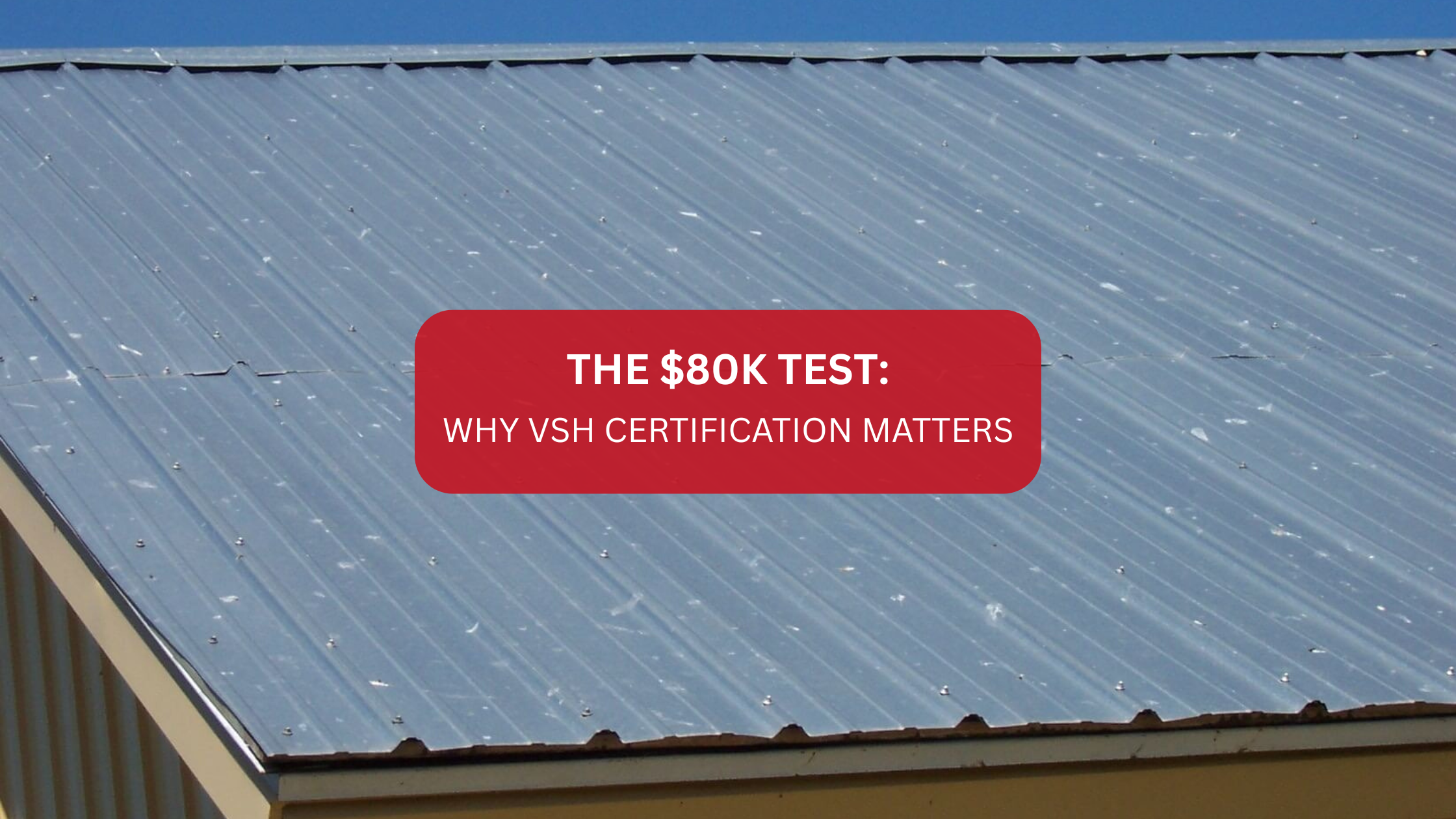

To earn a VSH rating, roof assemblies must pass FM Approvals testing under the ANSI FM 4470 standard. The process simulates extreme hail impact in size, energy, and aging conditions.

Here is how the testing works:

- A 2-inch diameter ice ball is launched at the roof assembly at 152–160 ft/s, creating about 53–58 ft-lbs of impact energy.

- Three different samples are tested to ensure durability:

- A brand new, unaged sample

- A sample that has been UV-weathered

- A sample that has been UV-weathered and heat-aged

- After impact testing, the roof membrane and seams are examined under magnification for cracks or splits. The cover board underneath cannot crack either.

This protocol is significantly more demanding than older severe hail tests. FM Global’s hail hazard zones, Moderate, Severe, and Very Severe, are based on historical storm data, modeled recurrence intervals, and observed hail sizes. The VSH zone spans multiple states, including parts of Texas, Oklahoma, Colorado, Wyoming, Nebraska, and the Dakotas.

Balancing Risk and Cost: What the Case Studies Show

Adopting VSH roofing comes with a price, but for many facilities, the investment pays off when you consider long-term risk mitigation. A case study by Benchmark, Inc. showed that a VSH-rated roof can cost 25–50 percent more than a like-kind severe hail system, depending on materials and design.

The extra cost is not just about premium materials. The VSH test also demands artificial weathering and impacts on cover boards, making it more difficult for an assembly to pass. Plus, the number of approved VSH assemblies is smaller than those for lower hail ratings, so material options may be more limited.

Manufacturers like SOPREMA hold nearly half of the VSH-rated roof assemblies listed in FM Global’s RoofNav database. Meanwhile, Sika Sarnafil became the first PVC roofing membrane to achieve VSH approval over gypsum cover board.

Why Facilities Should Pay Attention

Hail is not confined to a few hail alley states, and even buildings outside the most extreme zones can experience dangerous storms. Severe hail of two inches or more has occurred in states outside FM Global’s designated VSH area, based on NOAA’s data.

Here is what is at stake for facility operators:

- Schools might shut down or delay classes, disrupting students and staff.

- Hospitals or clinics could face water infiltration into sensitive areas, potentially compromising patient care or critical equipment.

- Manufacturing facilities may need to pause production, triggering supply chain delays, lost revenue, and costly downtime.

- Commercial properties risk not just physical damage, but operational and reputation risk, especially if they do not recover quickly.

VSH-rated roofs reduce the chance of catastrophic failures and emergency repairs. They also help facilities align with insurer expectations and national risk-management standards, making long-term planning more predictable.

Why Choose Coryell Roofing?

At Coryell Roofing, we do not just install roofs, we deliver hail protection strategies rooted in science. Here is how we put FM Global’s research and testing to work for our clients:

- Comprehensive Assessments We start with a detailed inspection of your facility, analyzing existing vulnerabilities and long-term risk.

- Expert System Design We design roof systems that meet or exceed VSH testing criteria, optimized for your building’s use, location, and budget.

- Proactive Maintenance Planning Our preventive maintenance programs help ensure your VSH system stays effective for years.

- Proven Experience Coryell Roofing has helped numerous clients recover from hail damage and prepare their buildings for future storms. We understand the disruption because we have seen it, repaired it, and helped people move forward stronger.

When you work with us, you are getting a partner who understands the human impact of weather risk and has the technical know-how to manage it.

Take Action: Protect Your Facility Today

If your building has not been evaluated against FM Global’s current VSH standards, now is the time. Schedule a Roof Performance Assessment with Coryell Roofing and let us help you safeguard your people, operations, and investments with a roof engineered for resilience.

Contact our team today to get started.

Coryell Roofing

Helping you protect what matters most—without the headache.